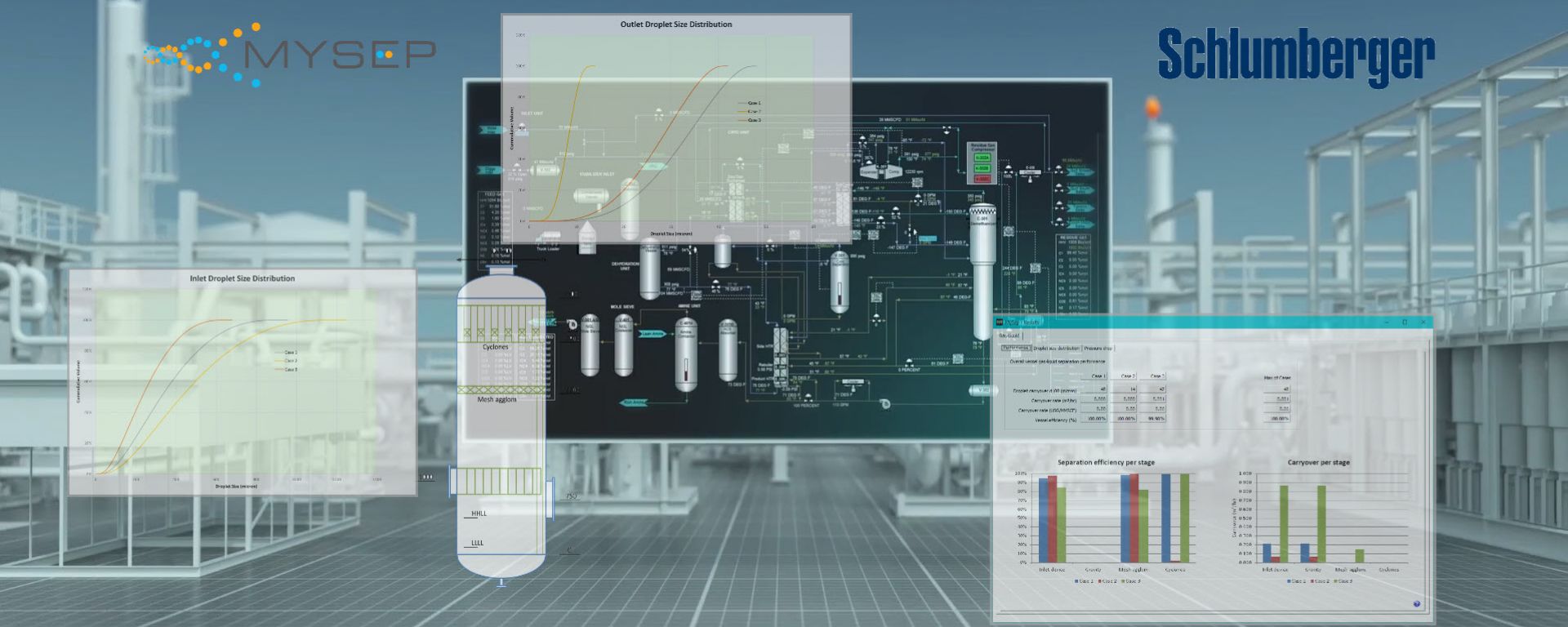

Schlumberger MySep Partnership

Schlumberger and MySep announce a partnership that provides a joint solution, delivering unprecedented capabilities for the design and rating of separators, and for evaluating their impact on the overall system in the exploration and production (E&P), and across the process industries.

The joint solution will be available through on-premises systems and through the cloud-based DELFI* cognitive E&P environment.

The Collaboration

Separation is a critical operation in production, midstream and downstream processing. Failures and malperformance are extremely costly. Proper separator design and operation are essential to the overall asset up-time and profitability. To help clients achieve this, both companies will work together seamlessly on projects: coupling the domain expertise of Schlumberger with MySep’s specialist knowledge in all aspects of phase separation.

Saad Kisra,

The DELFI environment is the only cloud ecosystem where MySep software products are commercially deployed. MySep Studio and MySep Engine are now available in the Process Facilities Engineer profile in the DELFI Petrotechnical Suite. MySep products join the Symmetry process software platform, and cutting-edge simulators OLGA* dynamic multiphase flow simulator, PIPESIM* steady-state multiphase flow simulator, and Flaresim* flare systems design and analysis software. Together these provide an integrated solution for optimisation of operations and comprehensive system design, across upstream, midstream and downstream Oil & Gas.

Saad Kisra, Global Head of Process Simulation, Schlumberger

Symmetry and MySep Studio

Full bi-directional communication between Symmetry and MySep Studio allows for rapid and detailed performance analysis of existing phase separation equipment. For greenfield projects MySep Studio can rapidly provide viable preliminary designs or fully optimized designs, with rigorous performance prediction and weight calculation. MySep's recommendations guide users to good practice when undertaking new and revamp design tasks. All common separation internals may be specified and modelled when rating equipment performance.

Symmetry and MySep Engine

MySep Engine provides fully rigorous gas-liquid separation calculation for separator unit operations within the Symmetry process simulation. This allows assessment of the overall impact of liquid carry-over on critical equipment, such as reciprocating or centrifugal compressors. It improves the fidelity of material and heat balances to facilitate better system optimum design or improved understanding to optimise operations.

MySep Expert

As well as MySep software, customers may also access the MySep Expert Service, subscribing through Schlumberger, to routinely validate separation performance analysis or to refine new-build and revamp designs. MySep's process separation experts support the client's engineers, with feedback and guidance on model configuration, and sensitivity to process operating conditions. Recommendations on practical options for design improvement are frequently provided.