Traditional Design versus MySep Approach

Take a close look at some key weaknesses in a traditional criteria-based approach to separator design, versus MySep's incremental performance analysis and good practice guidelines.

Typical Industry Guidelines

A number of traditional industry guidelines have evolved. These are often based purely on empirical methods and anecdotal recommendations.

Consider typical recommendations for a scrubber in hydrocarbon service at 30 barg with compression suction service where allowable carry-over requirement < 0.1 USG/MMSCF.

- Range of inlet devices cited: diverter plate, half pipe, vane type, cyclonic

- Overall vessel K-values within company accepted limits

- For vane pack demisting device, K-values in the range of 0.9 – 1.0 ft/s (0.274 – 0.305 m/s)

- Vane pack momentum limit: 20 lb/f s2 (29.8 kg/m s2)

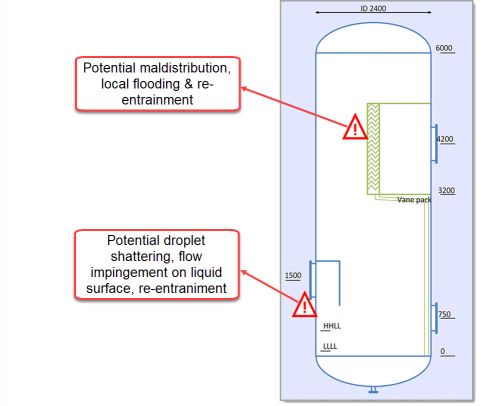

The above criteria and the configurations illustrated in traditional guidelines resulted in an installed arrangement as shown.

MySep Studio Guidelines

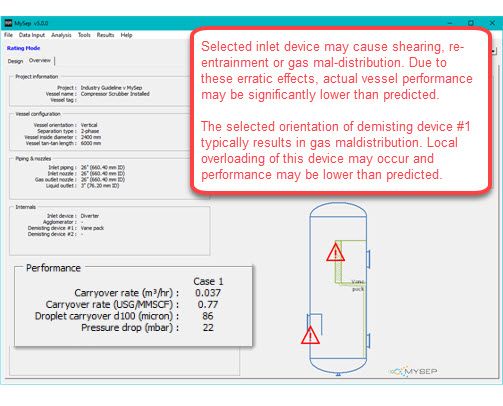

In MySep Studio rating mode, the geometry of the existing scrubber is replicated. Process operating conditions and phase flows are input. The key vapour phase and liquid phase properties are input directly or these may be readily imported from a process simulation.

The program gives warnings to indicate aspects of the configuration considered "undesirable."

In this case the type of inlet device can cause shear and shattering of droplets. It will promote impingement of the vapour flow on the liquid surface with risk of additional entrainment. The arrangement of the vane pack demisting device, with horizontal flow, requires the vapour to accelerate and turn. This promotes velocity maldistribution with risk of local flooding and re-entrainment.

Analysis in MySep Studio

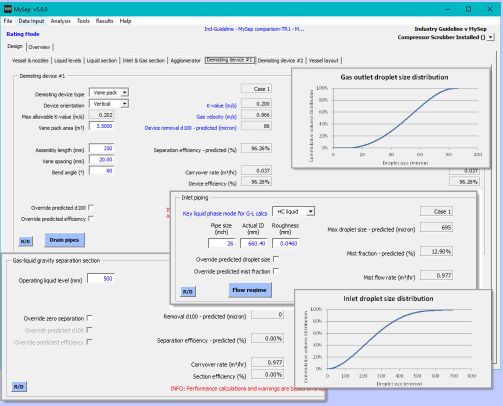

Using MySep Studio we see that an idealised analysis of the existing arrangement results in carry-over ≈ 0.8 USG/MMSCF with droplets of up to 86 μm.

The incremental analysis predicts that around 13% of the liquid in the inlet piping is introduced as mist, a dispersion with largest droplets ≤ 695 μm. Gravity is ineffective in removing these droplets and the operating conditions, coupled with the mist loading, determine that the demister will only remove droplets > 86 μm. The result is an overall carry-over exceeding specification (with non-idealities neglected).

Actual performance will be poorer than predicted, as the program warns, and Computational Fluid Dynamics (CFD) modelling would also be needed to achieve a comprehensive determination.

Retro-fit Remediation

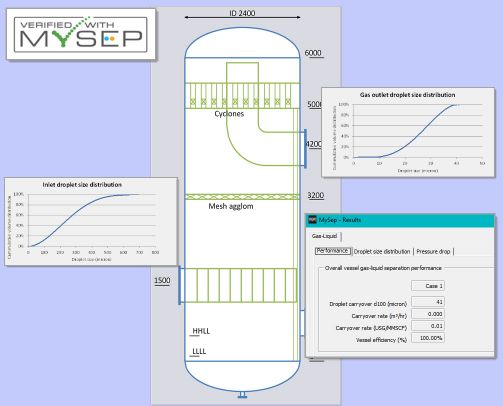

Using MySep Studio the engineer devised a retro-fit scheme to provide improved internals and give assurance that performance specifications were achieved.

A vane-type inlet device was deployed. A vertical flow mesh agglomerator was mounted upstream of a deck with 80 vertical flow demisting cyclones.

Predicted carry-over was reduced to 0.01 USG/MMSCF with droplets < 42 μm.

The agglomerator works effectively with the cyclones at high gas loading. At significant turndown, the mesh pad will provide all required separation capacity.

Scrubber Revamp Traditional Design v MySep Approach

See how MySep Studio software provides a route to design and revamp, based on analysis of separator performance. The white paper is a case document showing the MySep approach, starting from calculated mist fraction and droplet size distribution at inlet, through each separation stage to outlet. The engineer can consider a range of operating conditions and obtain a soundly-based prediction of carry-over performance.