Modelling Rigour: The Key to Unlocking Hidden Production Capacity

Across the oil and gas sector, digital twins have become central to the drive for efficiency, reliability, and sustainability. Yet many implementations still fall short of their potential — particularly when the underlying process models don’t fully reflect reality.

As the team at MySep has observed through multiple projects, one of the most underestimated areas in achieving an accurate digital twin lies in how we represent separation systems.

The Overlooked Bottleneck

Production facilities are complex ecosystems comprising reservoirs, pipelines, compressors, heat exchangers sometimes including stabiliser columns and absorption/contactor columns, and separation vessels— each unit-operation influencing overall throughput, energy consumption and product quality, to some degree.

In many cases, the true production constraint is hidden within the separation unit operations. Offshore and onshore productions facilities often apply hydrocarbon dewpoint limits for the gas export systems. When separation performance drifts from design intent, small amounts of liquid carry-over, entrained as droplets in the gas, can constitute the difference between operating safely and sustainably breaching product specifications.

As MySep’s experience has shown, these issues are rarely due to lack of technology — they stem from simplified process representations. A digital twin built on idealised assumptions will miss the nuances which characterise real separator behaviour.

Digital Twins Need Modelling Rigour

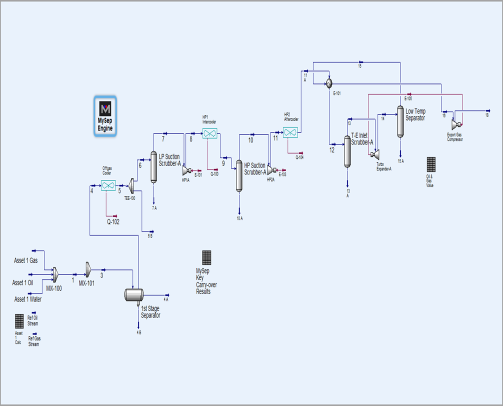

Modern simulation platforms such as Aspen HYSYS®, AVEVA™ PRO/II™ and AVEVA™ DYNSIM®, Honeywell UniSim® Design, KBC Petro-SIM®, Kongsberg K-Spice® and SLB Symmetry provide the backbone of most process Digital Twins. Whilst it is typical to model many process operations with rigour, including heat exchangers, pipelines, valves, pumps, compressors, controls etc with fully rigorous representations: simulator default separator models either, neglect carry-over, or require the user to specify arbitrary linear factors.

The MySep approach sees rigorous, physically-representative separator models embedded within the user’s simulation models. When separation physics — droplet size distributions, internal geometry, entrainment, coalescence and separation efficiency — are accurately captured, a Digital Twin gains a new level of predictive power.

This principle of modelling rigour enables engineers to make confident, data-driven decisions: understanding constraints, testing modifications virtually, and identifying opportunities that traditional models overlook.

Case Study: Overcoming a Dewpoint Constraint Offshore

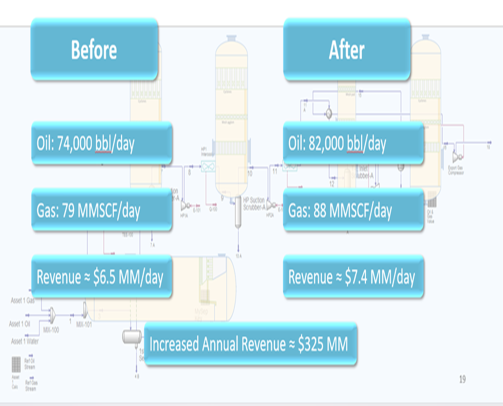

On a producing FPSO handling around 74,000 barrels of oil per day and 79 million standard cubic feet of gas, operators were struggling with a persistent bottleneck. The facility’s gas export system was limited by a hydrocarbon dewpoint specification, a critical operational constraint that ensures the gas delivered to the pipeline remains dry enough to prevent hydrocarbon condensation and hydrate formation during transport.

However, as production increased, the gas stream’s dewpoint began to rise — indicating higher levels of liquid hydrocarbons carried over from upstream separation. Pushing throughput beyond a certain point meant breaching the dewpoint specification.

From an engineering perspective, this created a dilemma, familiar across many facilities: the processing plant appeared mechanically sound, yet its capacity was capped well below its design potential. Conventional process simulations could not explain why. The models represented separators as ideal devices, unable to show the subtle interaction between liquid droplet entrainment, internal geometry, and phase behaviour that determined the real operating limit.

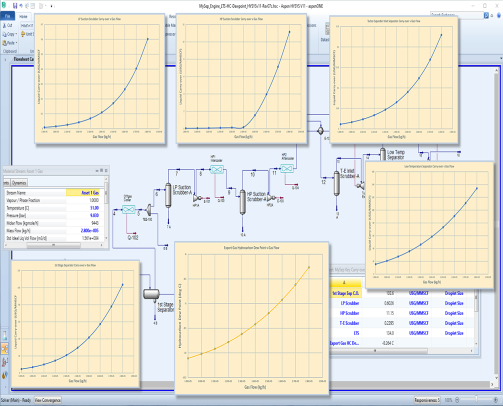

To understand the issue, engineers developed a process digital twin of the production train, integrating MySep’s rigorous separator models within a commercial simulator platform. For the first time, the model could replicate how small variations in gas and liquid flow affected entrainment and downstream dewpoint.

Through a series of “what-if” studies, the Digital Twin, activated with MySep Engine separator modelling, allowed the team to explore the impact of changes to operating conditions on the entire process system. This revealed carry-over of liquid with gas from the 1st stage separator and the various separators through the entire compression and dew-point control/NGL recovery process. The analysis revealed that ultimately, liquid mist carry-over in the low-temperature separator was excessive - a behavior invisible to conventional process models.

Utilising the MySep Studio software, retro-fit internals up-grades could be explored for each separator vessel. This demonstrated viable options for all vessels, and the overall process operational envelope could be explored, with these revamp configurations simulated in the digital twin.

The upgraded process provided improved droplet capture efficiency throughout, significantly reducing the amount of mist carried into the export gas stream even during high throughput operation.

In practice, this meant the facility could safely raise production rates without exceeding the dewpoint limit — a clear demonstration of how rigorous modelling and digital experimentation can identify low-cost, high-impact solutions long before any physical intervention is made.

The improvement unlocked an increase in production from 74,000 to 82,000 barrels of oil per day, and gas output from 79 to 88 MMSCFD, all while maintaining compliance with the dewpoint limit. The uplift equated to roughly $325 million in additional annual revenue — achieved with modest capital expenditure and executable in a short turnaround. This is typical of the results that readily derive from application of a MySep Engine activated Digital Twin.

The insight wasn’t in the hardware itself but in understanding how separation performance governed the whole process.

In this case the primary constrain was HC dewpoint, in others it could be:

- Fouling of compressor blading reducing efficiency and hence gas production capacity

- Fouling of pre-coolers and inter-coolers reducing compression capacity and hence gas production capacity

- Gas sweetening capacity reduction due to foaming in amine contactors caused by excess hydrocarbon carry-over

- Excessive consumption of solvents used for gas sweetening or dehydration caused by solvent carry-over

- Rapid degradation of gas dehydration molecular-sieve bed performance due to upstream hydrocarbon carry-over

From Off-line Studies to Online Optimisation

Building on such studies, several of MySep’s leading international operators customers are now exploring online digital twins that link live facility data directly to process models.

Real-time updates from the DCS feed into the digital twin, allowing operators to track predicted carry-over, droplet size, and separator efficiency as “virtual tags.” These continuously updated insights augment plant historian data and support AI-driven anomaly detection and maintenance forecasting.

This evolution moves digital twins from periodic analysis tools to continuous operational companions — offering an integrated view of process performance, safety, and profitability.

A Broader Perspective

Experience across multiple facilities confirms a simple truth: real Digital Twin value mandates modelling rigour.

Digital twins are only as good as the models they contain. By ensuring that separation — often the hidden bottleneck — is represented with sufficient physical depth, operators can uncover significant efficiency and revenue potential while maintaining compliance and integrity.

For MySep, this philosophy sits at the core of every project: combining process engineering science with digital innovation to help the industry make better, evidence-based operational decisions.