Testimonials

“MySep software provided us with pressure vessel process and vessel internals analysis that our engineering staff severely needed. The software is very flexible and efficient and the data output is superb. Our engineering team is much more efficient and can finish tasks in a timely manner using MySep. The data output is also very useful in our tender packages and for creating marketing materials. The MySep program has become an integral part of our engineering tool box.”

“I have the utmost respect for the achievements of the MySep team over the last years. You have truly put something together that the industry needs and the users want. At the same time you are contributing to the global education on separation, on which there is still a lot of work to do. This benefits everyone, the operators, contractors and separation equipment vendors."

Flow Processing Manager, TechnipFMC (FMC Technologies)

“After 3 months of using MySep, we have already 2 full success stories demonstrated on flare KOD’s design verification (One for a new Design and one for an existing retrofit design). It will definitely increase the level of expertise in our Team and add immediate valuable contribution in the future Projects (new and existing retrofits) by ensuring minimum sizing required dimensions at every step of a Project."

Process Engineering Section Leader, ADNOC Offshore

“The KL team would like to thank you for the training you provided over the last two-days. We all gained a lot from your extensive knowledge and experience it makes a big difference when the theory can be properly explained. I believe our team will be up to speed very quickly and making the most out of the software, as you said it’s not the case of just plugging in the numbers, you need to understand what you need to solve.”

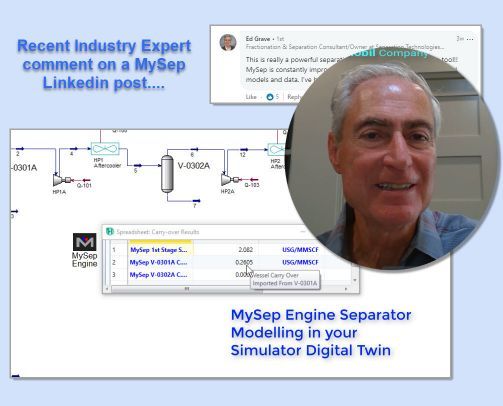

Expert Comment on MySep Linkedin Post

"This is really a powerful separation design and troubleshooting tool!! MySep is constantly improving the software based on solid technical models and data. I've been super impressed!!."

See the short video (to the left) of Ed's further comments.

Ed Grave, Fractionation & Separation Consultant/Owner at Separation Technologies Solutions, LLC, former separation and fractionation Subject Matter Expert, ExxonMobil.

More Testimonials

“MySep has become one of my favourite softwares and I will keep asking you questions about it in the following weeks.”

“We have been using MySep in Paris’ process department for the past year and it has proved very useful both for new designs and checking of existing separators. (troubleshooting or debottlenecking). The tool includes a full catalogue of vessel internals with associated performance curves. The technical support is of high quality.”

Lead Process Engineer, Head of Methods, Company Standards and Training, TotalEnergies

"On MySep support: “It is great – very responsive and technically savvy.”

“As far as investing ... dollars in all kinds of software, the investment in MySep was definitely a homerun.”

Facilities Engineering Manager, Anadarko/Oxy

"It was around 170 MMSCFD where [MySep] started to predict big problems with carryover and we experienced this in the facility.”

Facilities Engineering Manager, Anadarko/Oxy

“Indeed, due to the professional quality, ease of use, and state-of-the-art technology in MySep, I have been able to tell [my boss] that I give the software high marks.”

“Thank you for the discussions and demonstrations we had over the last couple of months on MySep software for rating and designing separators. The software is really easy to use, and from the checks that we have done we can conclude that it produces realistic results."

Eric Vos, Former Shell Technologist distillation and separation

“We extend our sincere appreciation to Tom Ralston and the MySep Pte Ltd team for their invaluable guidance during the recent training session on the Separator Sizing program, MySep, tailored specifically for the Heritage Engineering Team. The training was not only informative but also meticulously designed to align with the unique requirements of Heritage operations. Participants found the content highly relevant and beneficial, gaining practical insights that will undoubtedly enhance their work in heritage engineering. Tom Ralston and the MySep team's expertise and dedication ensured a comprehensive understanding of the program's functionalities, empowering the team to utilize it effectively in their day-to-day operations. We are immensely grateful for their efforts in facilitating such a valuable and impactful training session.”

Lead process engineer, Heritage Petroleum

“I think the training was superb. Few attendees that I talked to after the course are definitely looking forward to use MySep as soon as we can get access to our licenses. I appreciate everything you did in the class as well as helping us on our actual examples. Demos were very useful. I certainly had 3 great days for sure!”

Sr Process Engineer, BP