Simulation Users

Process simulation is used to design processes and to optimise the operation of existing plants in upstream, midstream and downstream oil and gas.

MySep Studio provides simulation users an environment to build detailed models of separation equipment. These can be saved for use in in process simulations that can benefit from rigorous representation of separator unit operations.

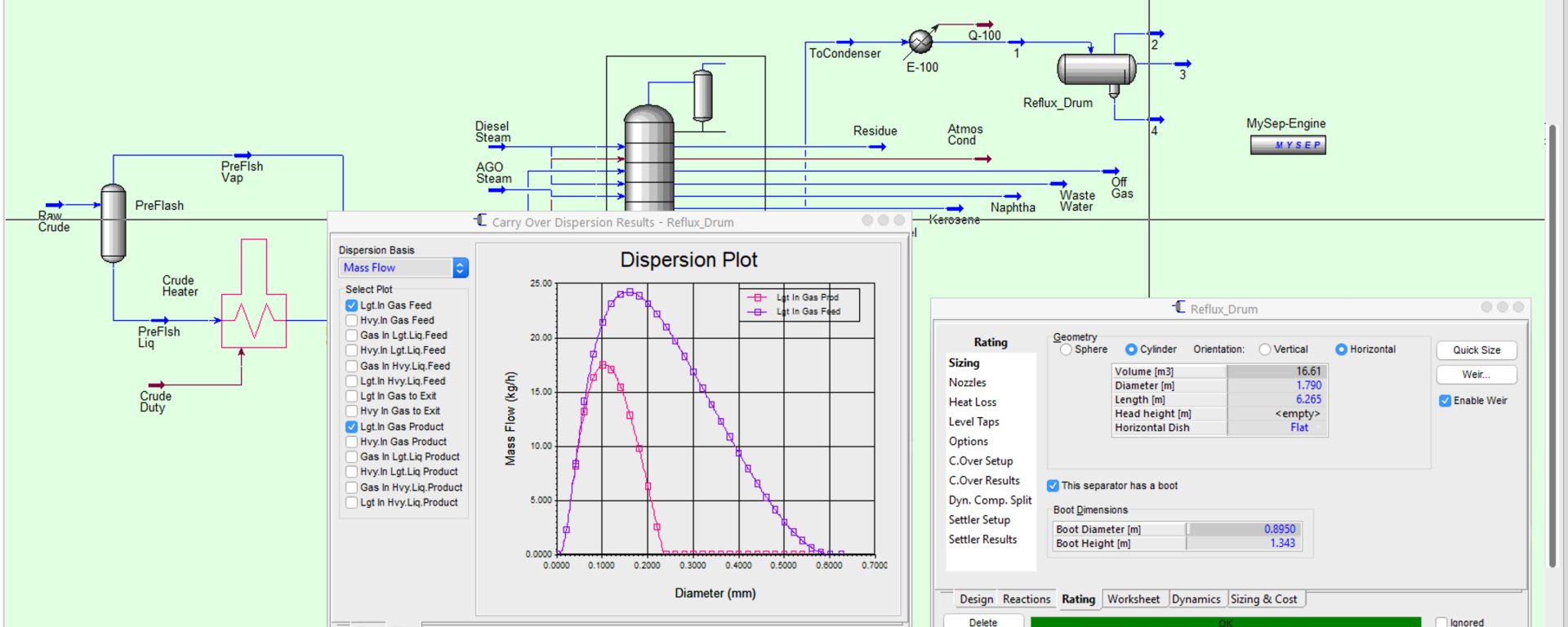

MySep Engine brings rigorous gas liquid separation modelling fully integrated with your steady-state and dynamic simulations.

MySep Benefits for Simulation users

More realistic & robust simulations with physically based rigour in separator unit operations. Dynamic & steady state modelling for design, optimisation of operation, troubleshooting and operator training systems.

Eliminate uncertainty associated with separator performance in every relevant simulation.

Carry-over in separator unit operations has direct impact on heat and material balance results. Many processes are significantly impacted by separation, and in these, it is vital to accurately represent separator behaviour rigorously in simulations.

MySep Engine embeds rigorous separator modelling in simulations with: Aspen HYSYS®, Honeywell UniSim® Design, AVEVA DYNSIM, AVEVA PRO/II, KBC Petro-SIM, Kongsberg K-Spice® and SLB Symmetry.

MySep-Studio allows engineers to define the configuration of separator models, these can then be stored in a special geometry file which can be loaded by a MySep Engine module within a simulation. Once saved with the simulation, the MySep Engine module enables the re-use of the rigorous separator models as and when required.

Setting up MySep Engine in Simulation Models

MySep Studio allows the configuration of separator models to precisely represent actual equipment. This includes the dimensions of the vessel and main process nozzles, liquid level settings, and the type of separation internals present within the vessel. This simple flow diagram outlines the main steps.