Videos

See benefits of MySep modelling for process applications and features of the products, MySep Engine and MySep Studio in the video links below.

MySep Studio V6.0 Video Preview

This short video offers a sneak peek into the primary attributes of the novel user interface showing how analysis graphics have been combined with numerical inputs and results to provide the user with immediate insights into performance. User ability to view key forms in combination is shown as is the new 3-D layout environment.

Expanding upon the solid foundation of its forerunners, MySep Studio V6.0 raises the bar of separation simulation and design for the 2020's and beyond.

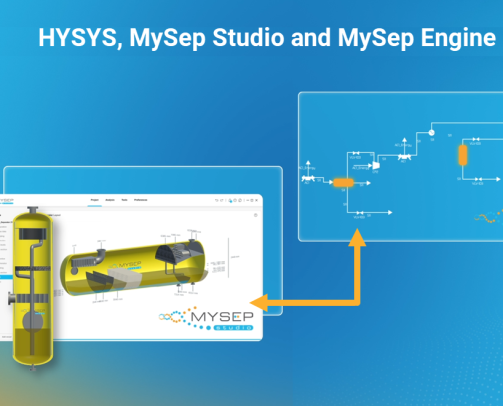

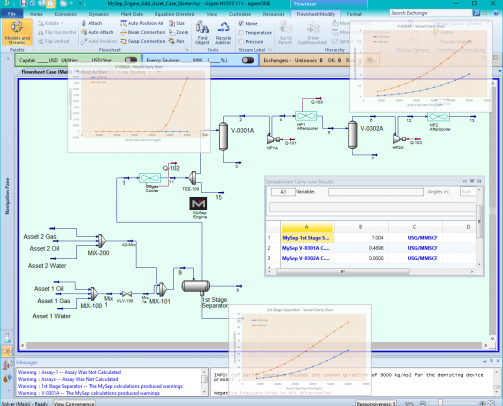

Aspen HYSYS Process Simulator & MySep Software for Rigorous Separation Modelling

This video, created in collaboration with AspenTech, demonstrates the integration of MySep Studio and MySep Engine with Aspen HYSYS. It previews how a system of separator models are defined with MySep Studio, and how MySep Engine embeds rigorous incremental modelling of gas-liquid separation in a HYSYS process simulation. The impact of rigorous separation modelling on the accuracy of the simulation is also introduced. [Duration 7m 48s]

MySep Margin Optimization

This 3 minute video illustrates how MySep technology helps Oil & Gas companies to optimize operations for increased revenue and margin. It is based around a production Digital Twin with MySep Engine modelling embedded in a steady state simulation. The example shows how optimizing separation performance on a facility, of modest scale, can can yield additional revenue of over $300 million per annum.

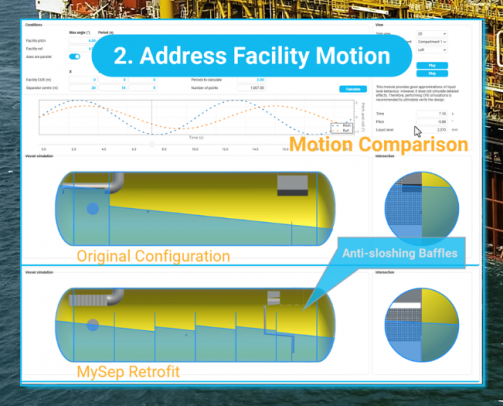

Separation & FPSOs – MySep Studio Performance & Motion

The performance of the separation system is pivotal to floating production and FPSO operations. This short video, featuring a 3-phase 1st stage separator, shows how MySep Studio software can remediate for separation performance issues and for facility motion.

MySep Studio for New Build Design

A step by step introduction to designing a production 3-phase separator with MySep Studio. Starting from a process simulation, use autosize, evaluate performance, export carry-over to simulation and generate a datasheet.

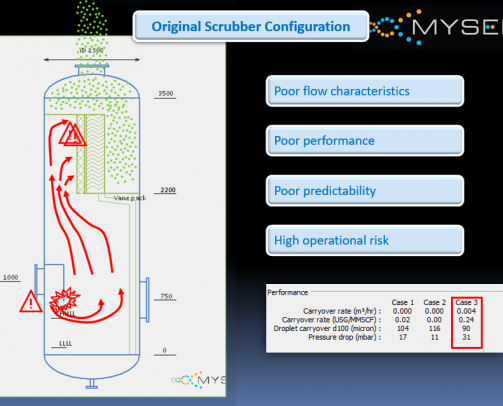

Fix Undesirable Scrubber Configurations

This video illustrates some key pitfalls in two-phase separator design. It shows MySep Studio performance analysis with warning messages highlighting poor design practice and likely operational impact. For this compressor suction scrubber, MySep Studio is used to develop a retro-fit solution which provides the assurance of satisfactory performance.

MySep Engine in a Steady-state Digital Twin

This video shows a Digital Twin, comprised of a HYSYS steady state simulation, with phase separators rigorously modelled by MySep Engine. The model is used to assess the impact of a potential tie-back to a new asset. Adding fluids to the existing production system - we need to verify that there is sufficient capacity to operate, without risk of damage to compressors, and un-planned shutdown.

Introduction to MySep Studio

For an offshore Oil & Gas Production application, this video steps through design of a 2-phase 1st Stage Separator, a 2nd Stage Separator with 3-phase capability and a Compressor Suction Scrubber. The importance of inlet conditions and droplet size distributions on resulting performance is shown. The effect of a plate pack coalescer on water-in-oil carry-over is shown as well illustrations of performance analysis for demisting devices, such as mesh pads and vane packs.

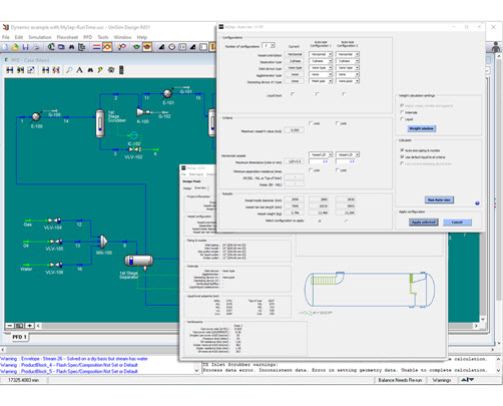

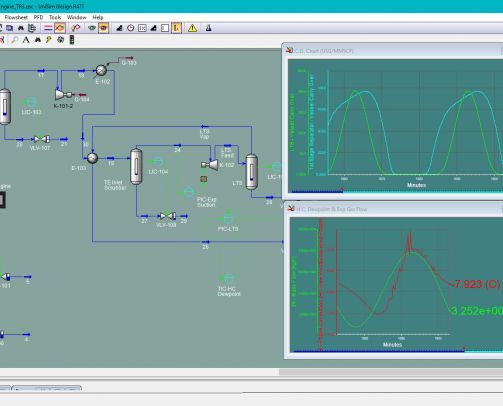

Slugging and Separation with MySep Engine in UniSim

This 2 minute video shows how MySep Engine, working within the UniSim Design simulator, reveals the extent to which slug flow in production pipework can affect the entire process operation. This underlines the value of rigorously modelling gas-liquid separation phenomena in dynamics.

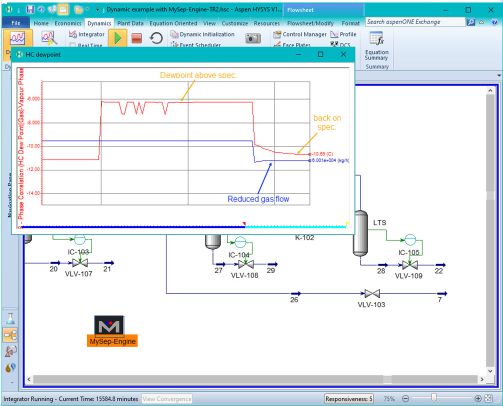

The value of MySep Engine in Process Simulations

In a dynamic simulation, the value of rigorous gas-liquid separation modelling is clearly revealed. The impact of carry-over in a low temperature separator is shown to strongly influence hydrocarbon dew point of export gas. There are potentially major consequences for the profitability of the operation.

Liquid carry-over fundamentally impacts heat and material balances. Effects on downstream separator, heat exchanger and compressor unit operations are discussed.