Kongsberg - MySep Alliance

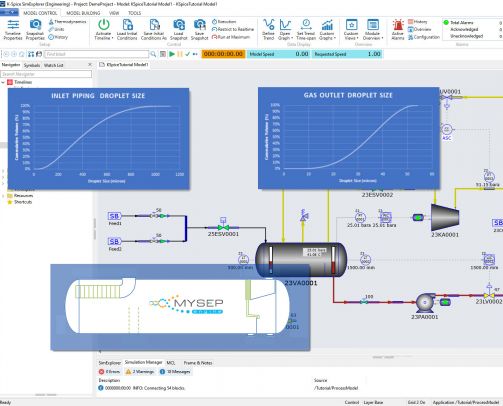

The Kongsberg - MySep alliance brings development of links between the K-Spice® simulator and MySep Engine. This will allow models of production processes and downstream processes to represent any two-phase or three-phase separator, with MySep’s rigorous gas-liquid methods. Models can be built in MySep Studio reflecting the as-built geometry and internals configuration of vessels. The MySep Engine application enables these models to fully integrate with K-Spice dynamic and steady state simulations.

K-Spice Process Simulation

Dynamic process simulation helps prepare for plant start-up and optimal operation and improves efficiency in all project phases, reducing cost and saving time. The ability to link in the rigorous separation modelling capability brings a new level of fidelity to the representation of upstream and downstream process for our oil & gas clients.

Stian Tangen, K-Spice Product Owner, Kongsberg Digital AS

K-Spice Simulation

The KONGSBERG multipurpose dynamic simulator is a powerful solution for detailed design and verification of processes and control systems throughout all life-of-field phases of an oil and gas field development from FEED to start-up.

The benefits of our K-Spice® solutions for production assurance include:

- Shorter project schedules

- Increased learning opportunities

- Improved safety

- Improved efficiency

- Reduced costs